The purpose of the revamp and modification is to address several issues, including poor burner combustion, draft limitations, and tube overheating, while also increasing product throughput. By replacing conventional burners with low NOx burners and using preheated combustion air, we can significantly improve efficiency without compromising NOx performance. This approach will enhance the overall system efficiency and allow for increased product throughput. Implementing these changes is a proven method to achieve better efficiency while maintaining or even improving NOx performance.

Burner Projects

Burner Studies

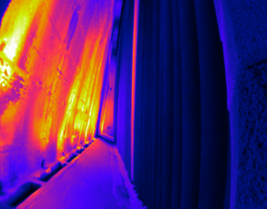

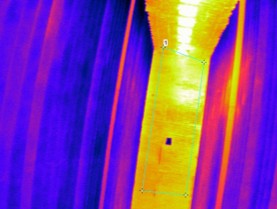

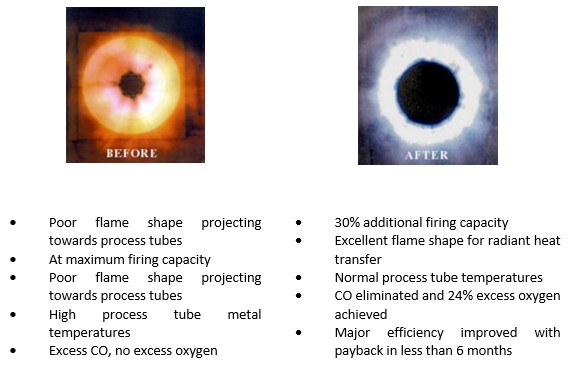

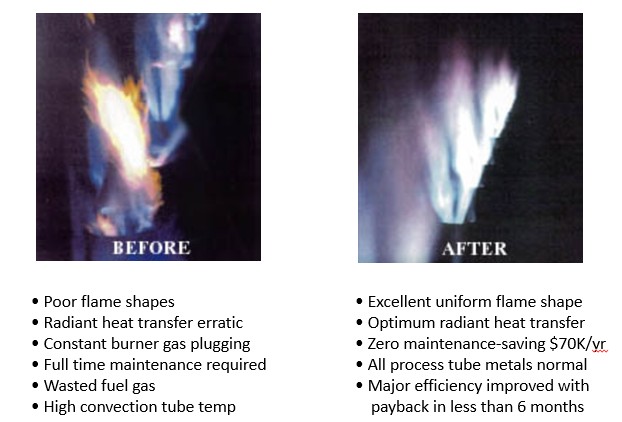

By performing regular burner evaluations, you can help to avoid costly repairs from poor burner operation. A complete burner evaluation by a qualified expert can identify burner issues and areas for improvement of operation, this information will be used in building a burner revamp/replacement plan to help customers achieve their operational goals. During an evaluation, a qualified burner expert will be sent to the site to examine the process heater, reformer, etc., and gather as much information as possible. Then a thorough examination of this data will allow us to offer a complete repair/revamp plan. This plan will give the customer options to make burner improvements, many times the best option is a burner revamp which entails replacing the internal burner parts with one of our Patent Pending burner kits. Sometimes burner revamps can be done online, this allows the customer to improve burner operations anytime not just during shutdowns. We also offer burner inspections before a turnaround; this helps us to identify items needing replacing and gives the customer more information to better plan turnaround activities. Many benefits can come from a burner tune-up with a few listed below.

- Increasing firing capacity

- Lowering NOx emissions

- Reducing chances of flame impingement

- Improve heat distribution

- Production increase

- Lower maintenance = increases savings